As people close up their homes for winter, sealing every open

gap, and installing thermal windows and insulation, they may be doing more than

making their home energy efficient. They

might be doing things that can make their family ill.

|

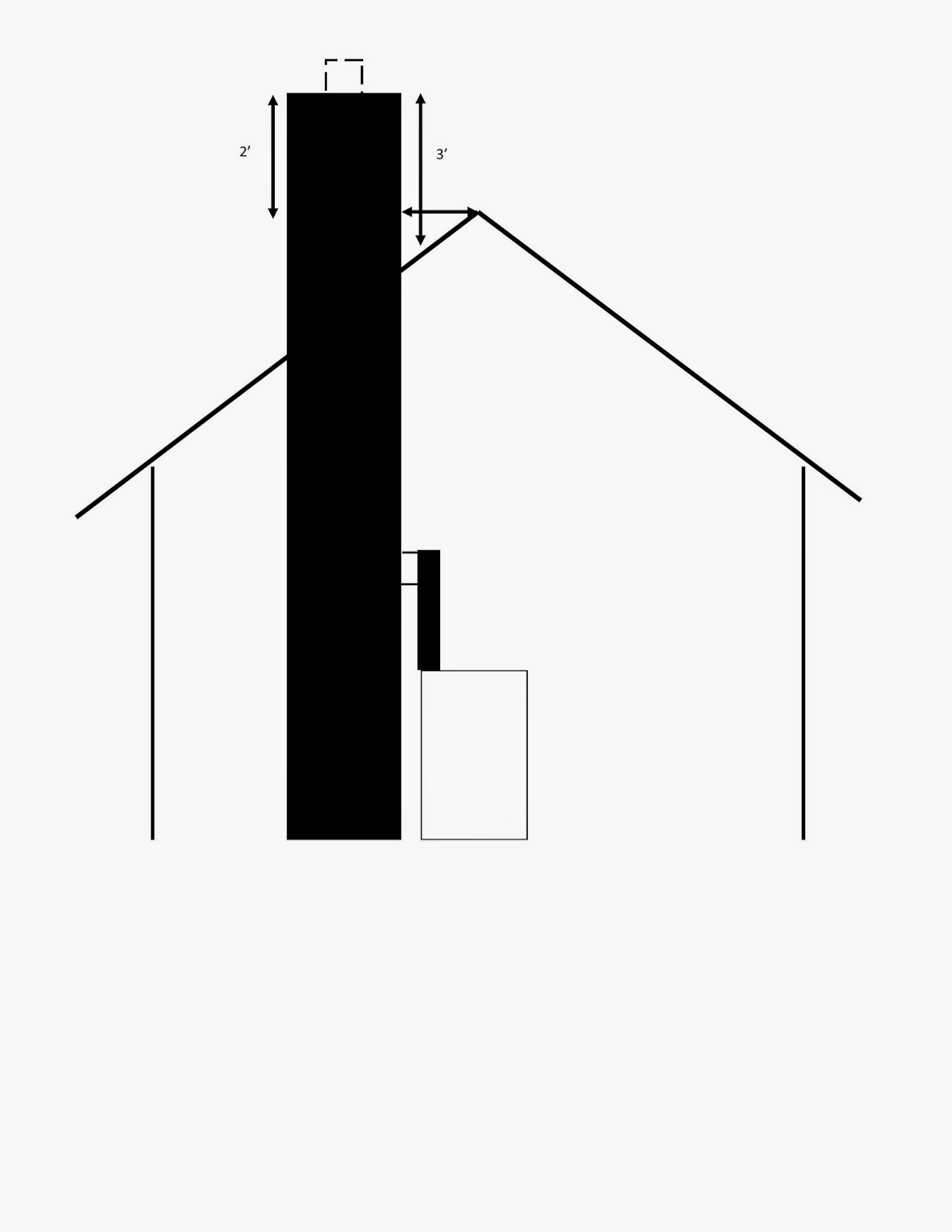

| A smoking fireplace is a sign of negative house pressure |

Houses need at least six air exchanges per day, according to

the Environmental Protection Agency. These air exchanges are necessary in order to

move out tobacco smoke, Carbon Dioxide, Carbon Monoxide, Nitrogen

Dioxide, Radon, and a host of other

chemicals such as Formaldehyde that off-gas from furniture, carpet and

woodwork. These air exchanges bring in

fresh air for the occupants to breathe.

Exacerbating the problem are appliances that take air out of

the house such as attic fans, range hoods, bathroom fans, clothes dryers, and

central vacuums. If the house is tightly constructed replacement air needs to

be introduced somehow.

Appliances such as furnaces, hot water heaters, fireplaces,

and wood-burning stoves need air for combustion, and they take house air for

this purpose. Open fireplaces are only

-10 - +10% efficient, and use heated air from the home, causing the furnace to

work harder. Even if an outside air

source is supplied to a fireplace in an attempt to use less house air, this is

often inadequate, and is arguably not the best solution. Cold air dumped on a hot fire cools it down,

causes it to burn inefficiently, and to produce more CO.

|

| High efficiency fireplace by Regency |

High-efficiency gas fireplace inserts are approximately 75% +

efficient and use no indoor air for combustion. Wood-burning fireplace inserts

and freestanding stoves are generally 70%+ efficient and use much less house air

for combustion than traditional open fireplaces do. These are good choices

whether a home has inadequate air for combustion or not. Other methods to

improve fireplace efficiency include installation of glass doors, use of a

grate heater, and improvement in design.

A Rumford or Prior Fire style fireplace is a better choice than a

standard style fireplace because it uses less air and is more efficient.

Efficient fireplaces or inserts use less wood than standard fireplaces to

produce the same amount of heat, so an added benefit is lower energy cost.

Another problem that can occur in larger homes or homes that

are tightly constructed is unbalanced house pressure. According to Dr. David Penney, professor of

Physiology and Adjunct Professor of Occupational and Environmental Health and

Wayne State University, and creator of COHeatquarters.com, Carbon Monoxide (CO)

is the most commonly encountered and pervasive poison in our environment. Dr.

Penney believes that long term exposure to low levels of CO (even those that

don’t register on a CO alarm) are capable of producing many debilitating residual effects on the

human body. This is called chronic CO poisoning, or CO Poisoning Syndrome.

Symptoms of negative house pressure are moisture condensation

on cold surfaces, smoking fireplaces or wood-burning stoves, difficulty

lighting a fire in a fireplace, CO

backup from gas and wood appliances, back-drafting of appliances (and CO), CO

detector alarms go off frequently, and cold air infiltration through

leaks. Children and pets may be more

affected than adults. If a person feels ill when at home, but better when

outside the home, this is an indication that something is wrong with the house.

Health effects associated with CO Poisoning Syndrome are

unexplained flu-like symptoms, headaches, dizziness, fatigue, confusion, joint

pain, muscle pain, chronic fatigue, vertigo, numbness, eye and nose irritation,

fainting, nausea, and in more serious cases, inability to wake up, asthma,

cancer, irreversible brain damage, or even death. Other symptoms include cognitive

and memory impairments, mood changes, depression, sensory and motor disorders,

and in more serious cases, seizures, balance problems, and tremors. These

symptoms can continue for weeks, months, or years after termination of CO exposure,

so it is imperative to assure good indoor air quality at all times at work and

at home.

Health effects associated with CO Poisoning Syndrome are

unexplained flu-like symptoms, headaches, dizziness, fatigue, confusion, joint

pain, muscle pain, chronic fatigue, vertigo, numbness, eye and nose irritation,

fainting, nausea, and in more serious cases, inability to wake up, asthma,

cancer, irreversible brain damage, or even death. Other symptoms include cognitive

and memory impairments, mood changes, depression, sensory and motor disorders,

and in more serious cases, seizures, balance problems, and tremors. These

symptoms can continue for weeks, months, or years after termination of CO exposure,

so it is imperative to assure good indoor air quality at all times at work and

at home.

Strategies to improve air quality:

2.

Maintain humidifiers and dehumidifiers and empty

water trays

3.

Replace air filters on schedule

4.

Turn on whole house fans or bathroom and kitchen

fans with doors or windows open occasionally in spring and summer (not during

cold weather)

6.

Install a whole-house ventilator to bring in

make-up air for appliances and fresh air to breathe

8.

Be sure clothes dryers are properly vented

outdoors and vents are cleaned twice per year

9.

Use a vented gas space heater or stove rather

than an un-vented gas appliance

10. Never

use kerosene heaters inside the house

12. Have

a professional CSIA Certified Chimney Sweep

inspect and clean furnace, fireplace, and wood stove flues annually and check for negative house pressure

13. Have

an energy specialist do a blower door test on the home, which will indicate

leaking areas and negative pressure issues. Some cities offer this service for free.

14. Be

sure to have a properly sized flue liner installed for a hot water heater if a

furnace is replaced and vented out the side of the house. The water heater will

no longer be able to vent on its own without the furnace and CO backup can

result

Sources:

----------------------------------------------------------------------------------------------------------------------

Marge Padgitt is the president of HearthMasters, Inc. chimney contracting company in Kansas City, MO. She is the editor of Wood-Fired Magazine, author of The Chimney and Hearth Pro's Resource Book and more books coming in 2016.